Industrial marking solutions are essential tools for manufacturers and businesses to identify, track, and manage their products throughout the supply chain. From printing batch numbers and barcodes to engraving serial numbers and logos, industrial marking plays a critical role in maintaining traceability, ensuring compliance, and enhancing product quality. As industries face increasing demands for transparency and accuracy, investing in the right marking solutions becomes crucial. This article delves into the various types of industrial marking solutions, their benefits, and how to choose the best one for your needs.

Types of Industrial Marking Solutions

Several industrial marking solutions are available, each suited for different applications and materials:

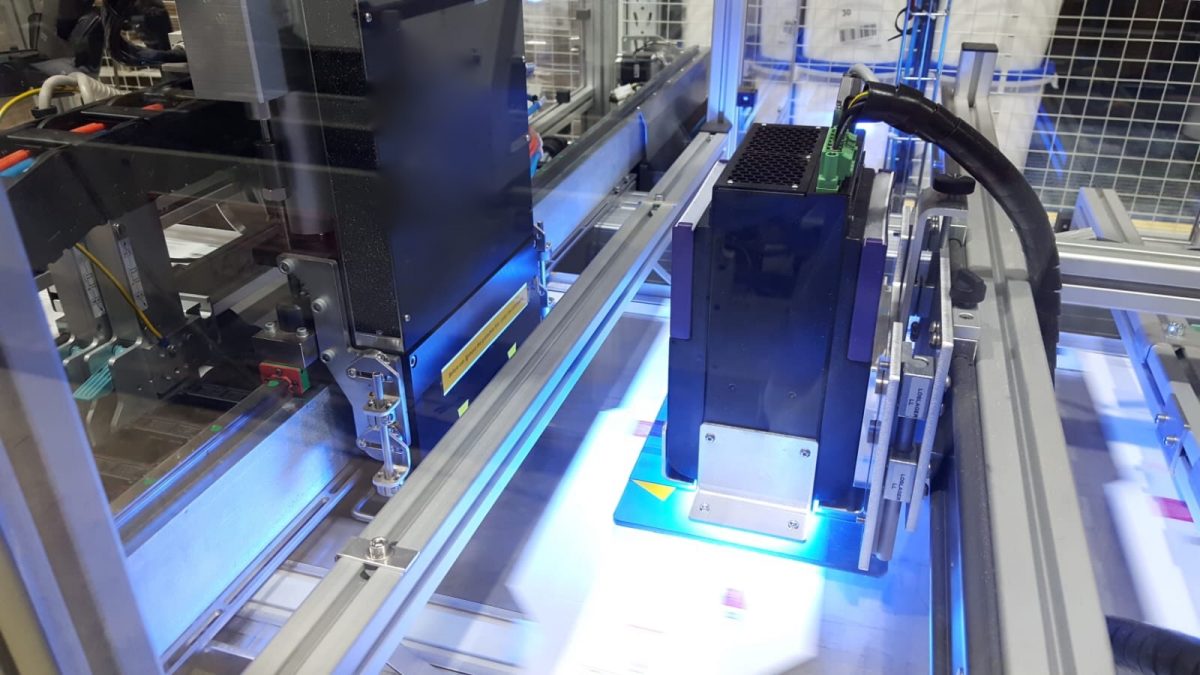

- Laser Marking: This non-contact method uses focused laser beams to engrave or mark information directly onto a surface. Laser marking is known for its precision, permanence, and ability to mark a wide range of materials, including metals, plastics, and ceramics.

- Inkjet Marking: Inkjet printers apply ink directly onto surfaces using non-contact technology, making them ideal for marking moving products on production lines. This method is often used for printing dates, barcodes, and logos on packaging materials.

- Dot Peen Marking: Dot peen marking machines use a stylus to create indentations or dots on the surface of a material. This method is suitable for marking metal and other hard surfaces, often used in automotive and aerospace industries for parts identification.

- Thermal Transfer Printing: This method uses heat to transfer ink from a ribbon onto a substrate, providing durable and high-resolution markings. Thermal transfer printing is commonly used for creating labels and flexible packaging.

- Electrochemical Etching: Electrochemical etching is a method for permanently marking metals, particularly stainless steel. It uses an electrolyte solution and an electrical current to create marks that are resistant to corrosion and wear.

Benefits of Industrial Marking Solutions

Implementing the right industrial marking solutions offers numerous benefits, such as:

- Enhanced Traceability: Industrial marking allows for easy tracking and identification of products throughout their lifecycle, from manufacturing to delivery, ensuring full traceability.

- Regulatory Compliance: Marking solutions help businesses comply with industry regulations by providing essential information like batch numbers, serial numbers, and expiration dates.

- Brand Protection: Clear and permanent markings help prevent counterfeiting and protect brand integrity, especially in high-value industries such as electronics and automotive.

- Operational Efficiency: Automated marking solutions reduce manual intervention, minimize errors, and increase production line efficiency.

- Cost Savings: High-quality, durable markings reduce the need for rework and product recalls, saving time and money in the long run.

Key Considerations When Choosing Industrial Marking Solutions

To select the most suitable industrial marking solution for your business, consider the following factors:

- Material Type: Different materials, such as metals, plastics, glass, or ceramics, may require specific marking methods (e.g., laser, inkjet) to achieve the desired results.

- Marking Speed and Volume: Evaluate your production line speed and the volume of products that need marking to choose a solution that meets your operational needs.

- Durability of Markings: Consider the environment in which your products will be used, including exposure to moisture, chemicals, or extreme temperatures, and choose a marking solution that offers the required durability.

- Integration and Automation: Look for marking solutions that can easily integrate into your existing production lines and support automation to minimize downtime and labor costs.

- Maintenance and Support: Opt for solutions from reputable suppliers that offer reliable support and maintenance services to ensure minimal disruptions.

Best Practices for Implementing Industrial Marking Solutions

To make the most of your industrial marking solutions, follow these best practices:

- Assess Your Needs: Begin by evaluating your specific marking requirements, including material type, production volume, and compliance needs.

- Choose the Right Technology: Select the most suitable marking method based on your product materials, environment, and operational goals.

- Invest in Training: Ensure your team is properly trained to operate and maintain the marking equipment to maximize efficiency and minimize errors.

- Conduct Regular Maintenance: Schedule routine maintenance to keep your marking equipment in optimal condition and prevent unexpected downtime.

- Monitor and Optimize: Continuously monitor the performance of your marking solutions and make adjustments as needed to improve quality and efficiency.

Industrial marking solutions are vital for businesses seeking to enhance product traceability, ensure regulatory compliance, and protect their brand. By understanding the different types of marking technologies and considering key factors when choosing a solution, companies can implement effective marking strategies that support their operational goals. Invest in the right marking solutions today to achieve greater efficiency, accuracy, and peace of mind in your industrial processes.